If A Vehicle Cant Be Aligned It Comes To Centerline

The Significance of Cradle Shift

Before you roll into that next wheel alignment, there's a crucial pit stop you don't want to miss – the pre-alignment inspection. This thorough check ensures a smooth ride, and one key player in this examination is the often-overlooked engine cradle. In this post, we'll uncover the vital role of the engine cradle and why it's a game-changer in the wheel alignment process.

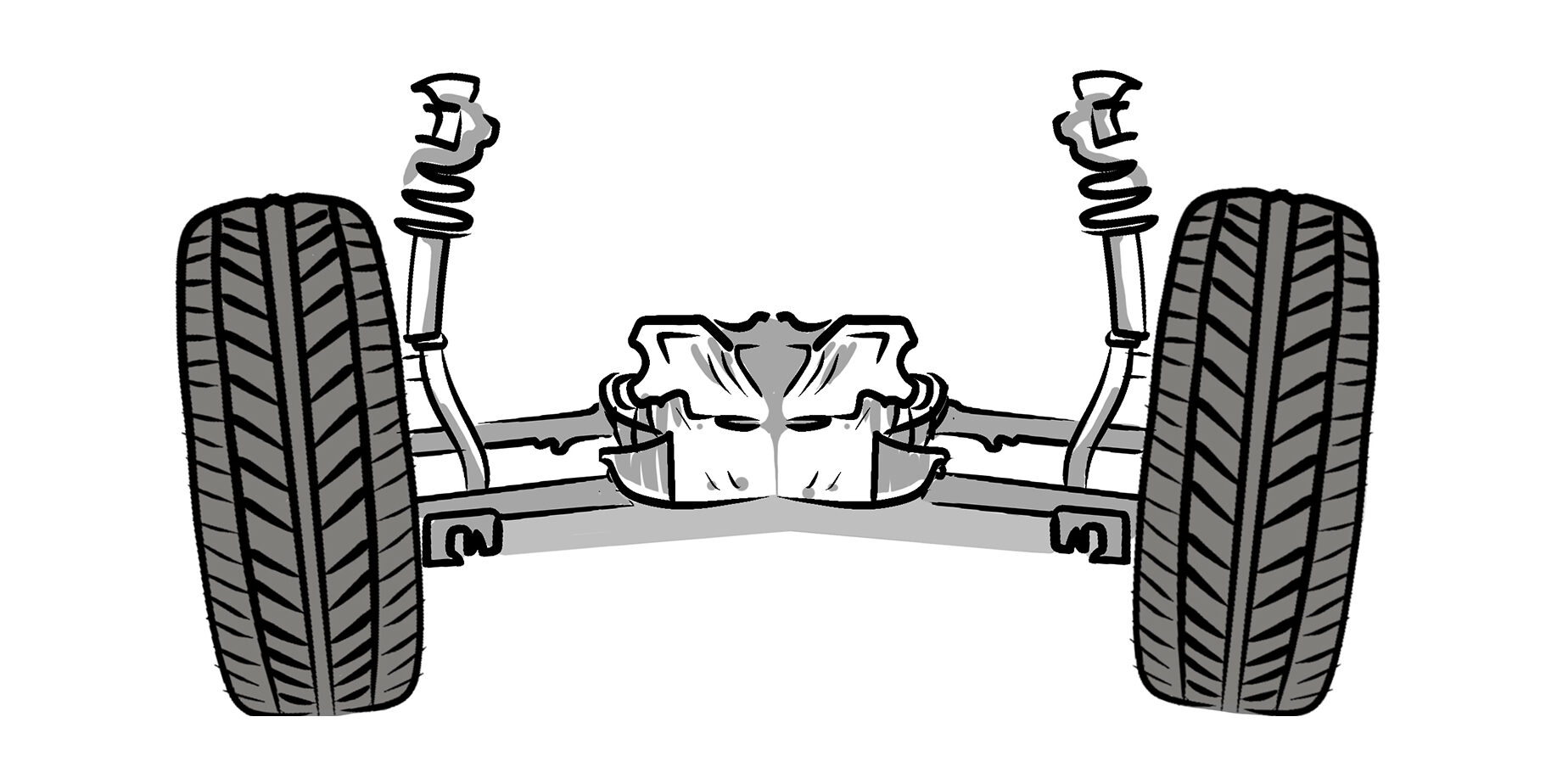

Exploring the Engine Cradle

The engine cradle isn't just another car part; it's the backbone of your vehicle's structure. Nestled within are motor mounts and lower control arms, securing the engine to the frame. We're about to delve into why the engine cradle deserves your attention before you hit the alignment station.

ENGINE CRADLE

CONTROL ARM

CONTROL ARM

An engine cradle that is bent or loosely fitted will lead to suboptimal alignment angles. Typically, most cradles come equipped with alignment holes to facilitate easy installation.

The Significance of Engine Cradle

Think of the engine cradle as the unsung hero in your vehicle's lineup. Any misalignment in this sturdy foundation can send ripples through the entire system, affecting those crucial alignment angles that keep your ride in check.

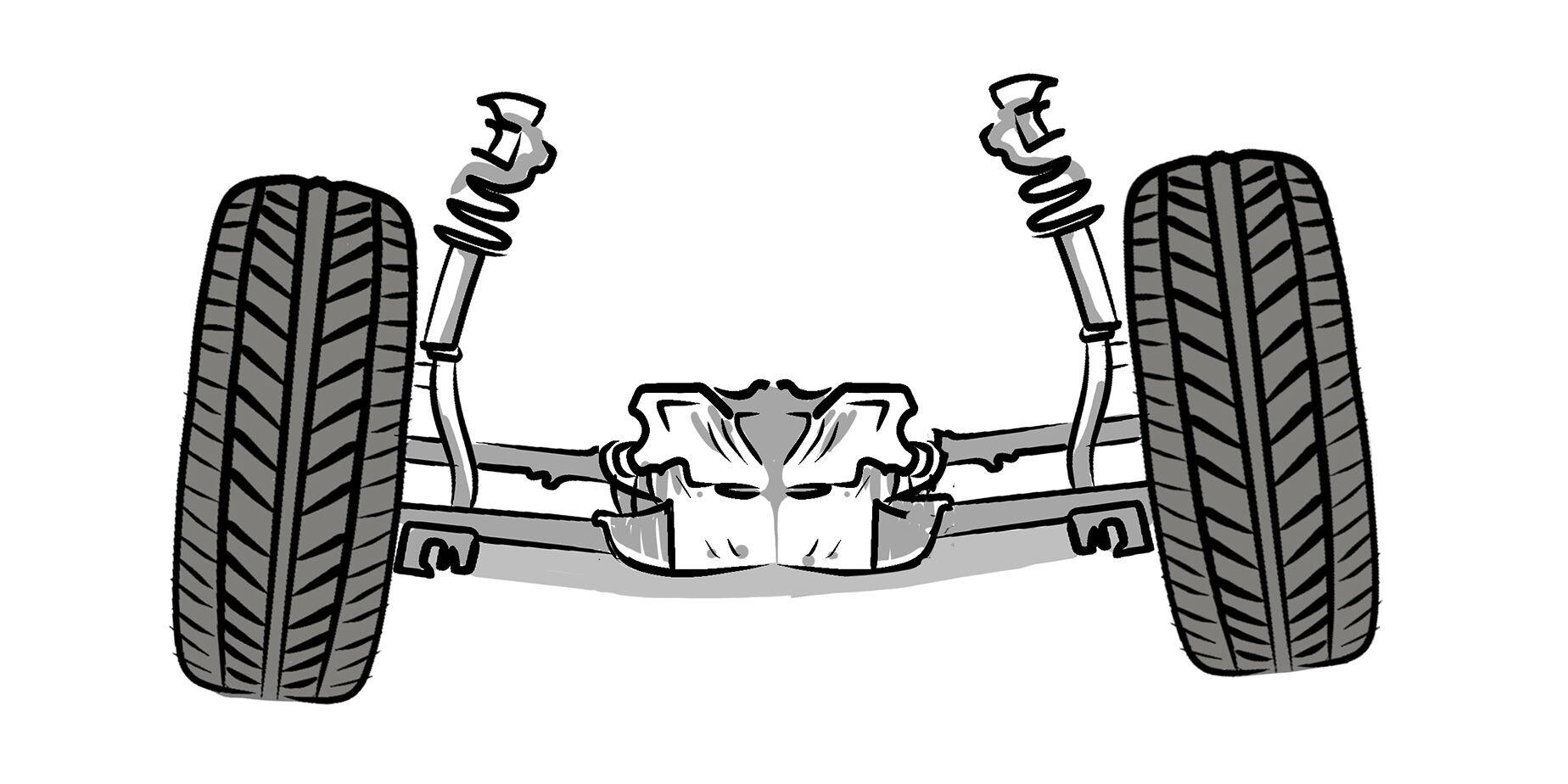

Affecting Alignment Angles

Lower control arms, snugly situated in the engine cradle, hold the power to sway your vehicle's alignment angles. When the engine cradle is out of sync, it messes with the camber angle – that tilt of your tire you might not pay much attention to. Too much camber can spell trouble, causing issues like pulling and uneven tire wear.

Positive Camber

Negative Camber

Vulnerability to Damage

Life on the road can be tough on your engine cradle, especially when potholes come into play. Collisions with potholes can leave your engine cradle in need of some TLC. Addressing and fixing any damage before attempting a wheel alignment is a non-negotiable step. After all, those lower control arms, intricately linked to the engine cradle, are the linchpin in alignment.

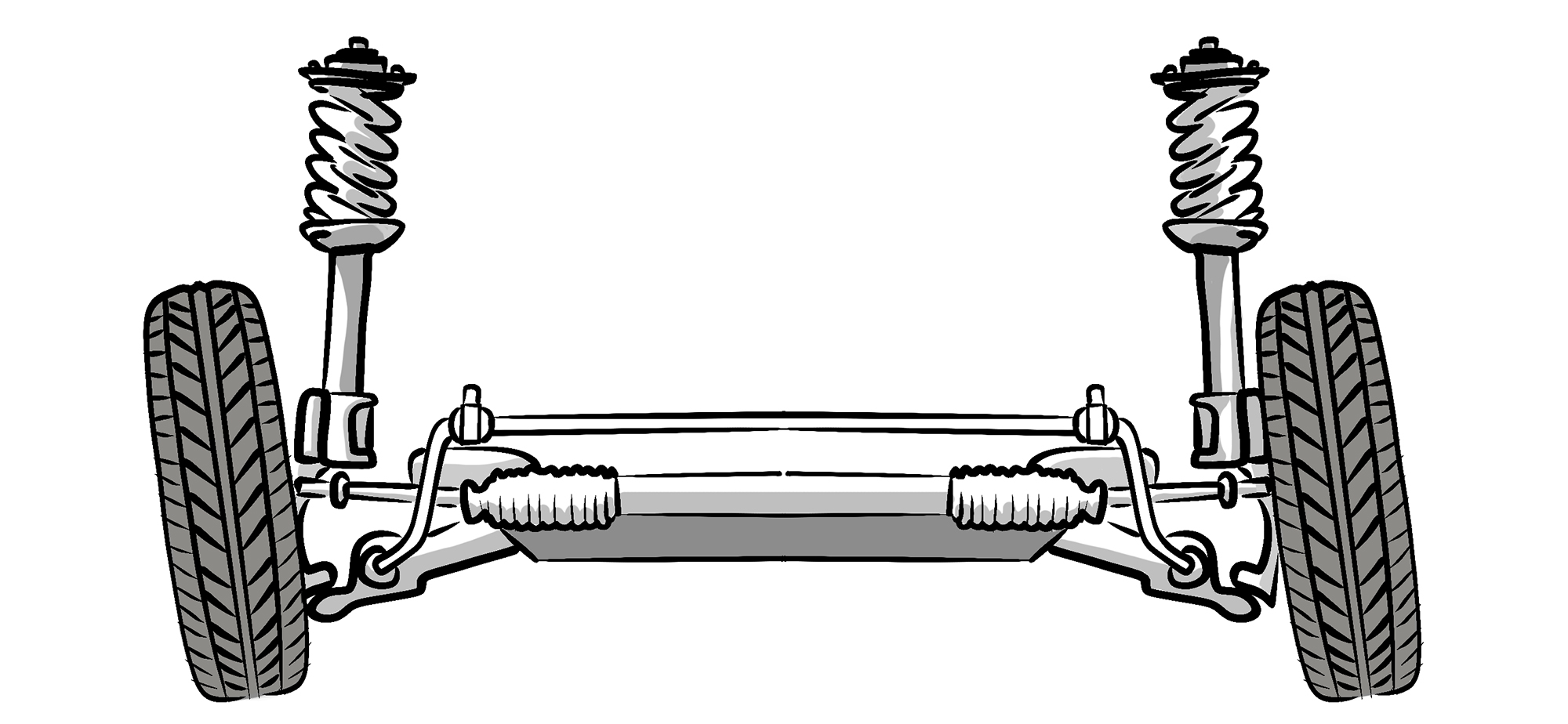

Balancing Camber Angles

Picture this: after a collision or repair work, your engine cradle shifts, causing one side to show off excessive negative camber, while the other flaunts positive camber. The result? Your vehicle may start pulling to one side. Fixing the misalignment of the engine cradle becomes your ticket to a successful wheel alignment.

ENGINE CRADLE

NEGATIVE CAMBER

POSITIVE CAMBER

Don't skip the pre-alignment inspection, with a special focus on the engine cradle. It's the first chapter in the book of a trouble-free driving experience. By spotting and addressing issues with the engine cradle, you lay the groundwork for a successful wheel alignment, ensuring even tire wear and optimal vehicle performance.

Centerline Frame & Auto: Three Decades of Expertise

With 30 years of dedicated chassis straightening experience, our team has honed the art of cradle shift to perfection. We understand the intricate interplay between the vehicle's components and the importance of precision in realigning the cradle. This wealth of experience has equipped us with a keen eye for identifying issues beyond the obvious, ensuring a comprehensive approach to chassis straightening.

At Centerline Frame and Auto, our commitment to excellence in chassis straightening goes beyond routine procedures – it's a dedication to providing drivers with the peace of mind that comes from knowing their vehicles are in the hands of seasoned professionals. Trust us to bring your vehicle back on track, ensuring a smooth and safe journey on the road.

Get in Touch

Got questions? No problem! We're here to help. Feel free to give us a call or fill out the contact form.

Address:

1480 Buerkle Rd, St Paul, MN 55110

Phone:

hours:

Monday to Friday: 8:00 am – 5:00 pm

Saturday: 9:00 am – 11:00 am Frame/Rust Estimates

Sunday: Closed